The plastic recycling industry is constantly evolving, confronting the significant challenge of increasingly complex and contaminated feedstock. To effectively address this, advanced plastic recycling production lines offer a solution, moving beyond traditional methods that often struggle with heterogeneous streams. This leads to diminished recovery rates and untapped resource potential. Recognizing these industry-wide hurdles, we have developed specialized plastic recycling equipment engineered to process intricate feedstocks and optimize resource recovery. This article will explore 3 key ways that these advanced production lines empower recyclers to handle challenging materials, enhance output quality, and ultimately improve profitability, maximizing the value derived from complex waste.

Understanding the Challenges of Complex Feedstocks in Plastic Recycling

Modern waste streams present significant hurdles for plastic recycling. Recyclers frequently encounter complex plastic waste such as post-consumer mixed plastics (PE, PP, PET, PVC, etc.) with varying degrees of contamination, industrial plastic waste containing additives, pigments, or multiple layers, end-of-life electronics plastics with embedded components, and agricultural films contaminated with soil and organic matter. These diverse and often contaminated materials pose substantial obstacles for conventional recycling processes. Inefficiencies in sorting can lead to cross-contamination, the difficulty in removing stubborn contaminants can compromise the quality of recycled materials, and the inherent differences in material properties can limit the applicability of single-stream processing techniques. Successfully navigating these complexities is paramount for achieving higher overall recycling rates, minimizing reliance on landfill disposal, and fostering a truly circular economy for plastics.

Advanced Plastic Recycling Production Lines : Addressing the Needs of the Industry

To overcome the limitations of traditional methods when dealing with complex feedstocks, advanced plastic recycling production lines, like those from Geording, have been developed. These high-efficiency plastic recycling systems integrate cutting-edge technologies at each stage of the recycling process to ensure efficient processing and the production of high-quality output materials. Here are 3 key ways these advanced lines boost the value of complex waste :

Way 1 : Enhanced Material Recovery through Advanced Separation and Purification.

Sophisticated pre-processing systems, designed specifically for complex feedstocks, employ advanced intelligent sorting technologies to accurately separate various plastic types and remove non-plastic contaminants with exceptional efficiency and precision. In conjunction with robust, high-efficiency shredding and grinding systems, these production lines maximize the recovery of usable plastic materials from even the most mixed waste streams. Multi-stage washing and decontamination processes, utilizing tailored washing solutions and specialized contaminant removal techniques, further ensure that stubborn impurities are effectively eliminated, resulting in cleaner and more valuable recycled plastic flakes.

Way 2 : Production of Higher Quality Recyclates for Broader Applications.

Precise extrusion and pelletizing systems are pivotal in transforming cleaned plastic flakes into high-quality, uniform granules. The advanced machinery is engineered with multi-material compatibility, enabling the processing of a wider range of recycled plastic types. In addition, we have successfully developed a diversified screen changer filter system and recently enhanced our production line with an automatic screen changer module. This innovative advancement not only improves material filtration precision but also significantly optimizes production efficiency, ensuring that the granules meet the stringent requirements of downstream manufacturing applications, thereby elevating their market value and broadening their range of applications.

Way 3 : Diversification of Output Streams for Maximum Resource Utilization.

Advanced plastic recycling production lines can also incorporate optional modules like RDF/SRF (Refuse-Derived Fuel/Solid Recovered Fuel) production and material compaction into bricks. For plastic fractions within complex waste streams that are not economically or technically feasible for mechanical recycling, integration with RDF/SRF production allows for the conversion of these materials into valuable energy resources. Similarly, the application of material compaction into bricks offers a high-value reuse pathway for specific mixed plastic waste streams in the construction industry. This diversification ensures that a greater proportion of complex waste is utilized, maximizing its overall value.

Geording’s Advanced Plastic Recycling Production Line : Engineered for Efficiency

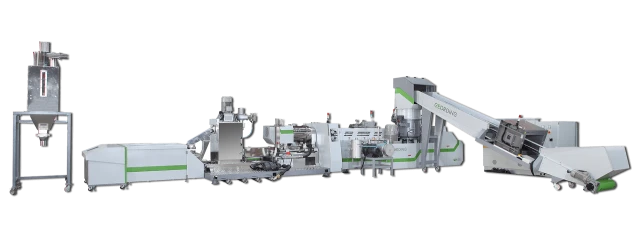

Geording’s advanced plastic recycling production lines are meticulously designed and engineered to efficiently process complex plastic waste streams through a series of key stages : robust crushing and shredding, effective washing, thorough drying, precise pelletizing, culminating in accurate batch weighing of the final product. Our robust crushing and shredding systems are capable of handling diverse plastic materials, breaking them down into manageable sizes for subsequent processing. Following this, our multi-stage washing process effectively removes contaminants, ensuring the cleanliness of the plastic flakes. The integrated drying stage optimizes moisture content, preparing the material for the crucial pelletizing phase, where high-quality, uniform granules are produced. Finally, our automated batch weighing system ensures accurate measurement of the recycled plastic pellets, facilitating quality control and efficient inventory management for recyclers. This comprehensive and integrated approach allows our production lines to maximize material recovery and deliver high-value recycled plastics.

-

Crushing and Shredding

\

\

-

Washing

-

drying

-

pelletizing

-

batch weighing

Our Role in Advancing Plastic Recycling Capabilities for Complex Waste

At Geording, we have established ourselves as a key provider of these advanced plastic recycling solutions, delivering reliable and effective plastic recycling equipment that directly addresses the three key ways outlined above. Our expertise and experience in handling complex feedstocks are demonstrated in projects such as the one undertaken for the Osaka Government in Japan. For this project, Geording provided a comprehensive solution for recycling construction waste, encompassing everything from the initial plant layout and the entire production line design to the specifics of water and electricity connections and storage solutions, all tailored to the client's unique requirements. By offering customized production line designs, as showcased in the Osaka project, we help recycling operations boost the value derived from complex waste streams, leading to improved profitability and a more sustainable future.

Advanced Plastic Recycling - A Sustainable Solution for Complex Waste

Adopting advanced plastic recycling production lines, such as those offered by Geording, is crucial for establishing a sustainable approach to managing complex plastic waste. By focusing on enhanced material recovery, higher quality recyclates, and diversified output streams, these technologies pave the way for a more environmentally responsible and economically viable future for the industry. To explore how Geording can help you maximize the value of your complex plastic waste and request a quote, contact us today.