The growing concern over plastic waste has led industries to seek more efficient recycling solutions. This article aims to explore the role of plastic granulators in the recycling process, highlighting their importance in breaking down waste into reusable granules. By understanding what a granulator is and its applications, businesses can make informed decisions to enhance their recycling efforts and contribute to a more sustainable future.

Types of Plastic Granulators

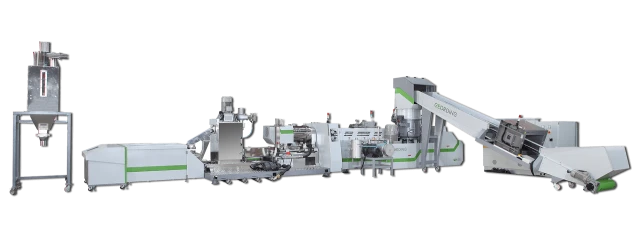

Plastic granulators come in several types, each designed to meet specific recycling needs. Edge material granulators are typically used for small-scale applications, handling scrap right at the molding machine. Shredder integrated granulators are designed for larger-scale operations, capable of processing significant volumes of plastic waste. Force feeding granulators are ideal for bulky and tough materials, such as pipes and thick plastic sheets. Each type has unique features tailored to specific industrial needs. Geording Machinery's products, such as the two stages extruder, not only offer high-efficiency particle processing capabilities but also feature a high-quality two-stage filtration system, which helps maintain the stability and quality of the materials during the processing.

Key Features and Considerations

When selecting a plastic granulator, several factors need to be considered, including the type of plastic to be processed, the required granule size, and the machine's capacity. The design of the input system plays a critical role in the granulator's efficiency, influencing the quality of the output and the machine's durability. For example, machines like those offered by Geording Machinery incorporate advanced features to enhance efficiency and longevity, ensuring consistent and high-quality output.

The Role of Granulators in Sustainability

The use of plastic granulators in recycling is not just about reducing waste but also about creating a circular economy. By converting plastic waste into granules, these machines enable the material to be reused in new products, thus reducing the demand for virgin plastic. This process not only conserves resources but also minimizes environmental impact.

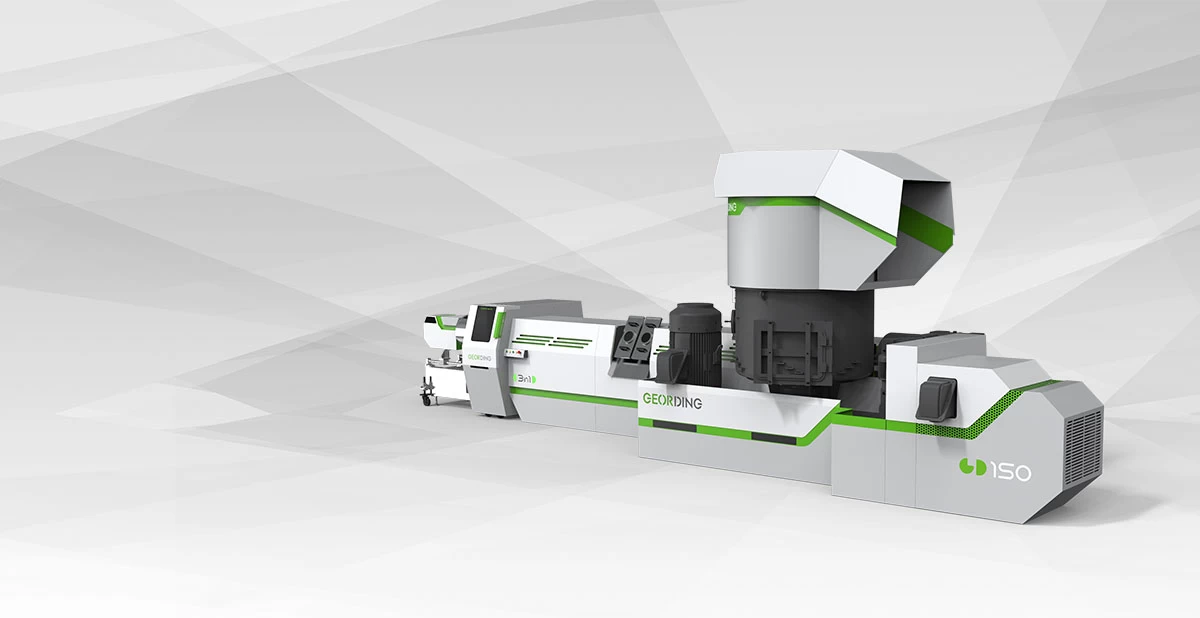

Explore Advanced Solutions

For businesses looking to invest in top-of-the-line granulation technology, exploring options like the compounding machines from Geording Machinery can provide advanced solutions tailored to specific recycling needs. These machines offer a range of features designed to optimize the recycling process, from efficient feeding systems to robust cutting mechanisms.

These machines offer a range of features designed to optimize the recycling process, from efficient feeding systems to robust cutting mechanisms. The three-in-one system, side feeding, force feeding integrate water ring cutting (Die face cutting ), and strand cutting are suitable for various materials, simplifying production processes and enhancing production efficiency.

If you have any product inquiries or need further assistance, please contact us.