Around the world, wherever human activity exists, there are plastic products—they've become an indispensable part of everyone's daily life.

But did you know that the world generates approximately 400 million tons of plastic annually, yet the cumulative recycling rate is less than 10%?

Facing the challenges brought by plastics, not only must individuals adopt eco-friendly habits, but businesses must also actively transform to embrace a circular economy to meet market demands.

Promoting a circular economy for plastics offers businesses more than just reduced production costs. It also aligns with the ESG trends of European and American markets, enhances brand image, and boosts corporate trustworthiness.

Ⅰ. Significant Demand for Recycling Post-Consumer Plastics

Commonly used disposable plastic items are lightweight and convenient, leading to mass production and a "use-and-throw-away" culture, making it hard to reuse these plastics at the consumer level. These plastic film waste materials not only exist in large quantities but also exhibit a high demand for recycling:

1. Packaging Materials

• Food Packaging Films: Such as bread bags, frozen food bags, snack packaging films, etc.

• Industrial Packaging Films: Plastic films used for product packaging, such as roll-stock packaging films and protective outer films.

• Courier Bags:Plastic bags used in logistics and e-commerce, often made of PE or PP material.

2. Agricultural Plastic Waste

• Agricultural Film: Plastic films covering farmland, primarily made of PE, used for moisture retention and weed control.

• Greenhouse Films: Plastic films used in greenhouse farming, requiring recycling after the end of their lifespan.

• Silage Wrap: Plastic films for wrapping silage.

3. Household and Consumer Waste

• Shopping Bags: Plastic bags used in supermarkets and convenience stores.

• Garbage Bags: Plastic trash bags generated in homes and commercial areas.

• Cling Wrap: PE cling films used for food preservation.

4. Commercial and Retail Waste

• Pallet Wrap Film: Plastic films used for bundling and transporting goods, commonly seen in logistics and warehousing.

• Promotional Films:Outdoor advertising plastic films used for promotions.

Ⅱ. Dirty Plastic: Difficult to Process? GEORDING Makes Recycling Easy!

The above types of plastic waste are often contaminated in their usage environments, posing significant challenges during recycling:

- Packaging Materials

Food packaging films and courier bags are often multi-layered with different materials, making separation during recycling difficult. Additionally, residues like grease and food particles complicate the cleaning process, consuming more resources. - Agricultural Plastic Waste

Exposed to natural environments for long periods, these often carry dirt and weeds, and may degrade due to sunlight and rain. - Household and Commercial Waste

While sources are stable, contaminants vary. Garbage bags and shopping bags are frequently mixed with household waste, requiring extra sorting. For commercial waste like promotional films and stretch films, issues such as ink and UV degradation further increase recycling difficulties.

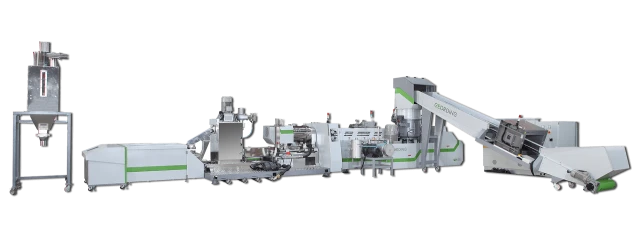

To address these challenges, GEORDING's Crushing, Washing, and Drying Whole Plant Facility for Plastic Film—specialized for film plastics—offers an effective solution to reduce collection and processing costs:

- Crushing Machine (Washing-Specific): Precisely controls material while enhancing cleanliness.

- Rubbing Drying Machine: Specially designed single-screw mechanism efficiently squeezes and stabilizes material output with low power consumption. For higher production demands, series configurations can achieve up to 2,000 kg/hour.

- Floating Tank: Customizable in quantity based on material cleanliness, with added work platforms for easy monitoring.

- Rolling Floating Tank: Utilizes density differences to separate raw materials from contaminants, improving cleaning efficiency.

- Horizontal Washing/Centrifugal Dryer: Combines washing and drying for maximum efficiency.

- Cable Raceway: Protects cables, ensuring easy installation and maintenance.

- Optional & Custom Solutions: Options include additional crushers, hydraulic cutters, large storage tanks, or mixing tanks. For unresolved issues, contact us to customize solutions tailored to your needs.

Ⅲ. GEORDING Offers More Than You Imagine

- Efficient Cleaning and Processing

The washing-specific crushing machine precisely controls material and effectively removes dust and dirt during the preliminary crushing stage. When paired with high-speed washers, it thoroughly separates mud and impurities, while the floating tank further removes high-density contaminants, ensuring clean, uncontaminated plastic materials. - Preventing Microplastics from Polluting Ecosystems

The system effectively removes residual pollutants during the cleaning process, preventing untreated plastic waste from entering the environment and degrading into microplastics. This is crucial for protecting marine ecosystems and biodiversity, reducing the long-term environmental impact of plastic waste. - Promoting Recycling and Reducing Resource Waste

The floating tank system separates raw materials and contaminants by density, significantly improving the purity of recycled materials. This allows for the production of high-value recycled plastics, converting waste into reusable resources, and reducing dependency on virgin materials like petroleum. - Minimizing Water Consumption and Pollution

The horizontal washer/centrifugal dryer integrates washing and drying using friction and stirring technology to thoroughly clean and dehydrate plastic waste. This design significantly reduces water usage during cleaning and eases wastewater treatment, further protecting water bodies. - Energy Conservation for Carbon NeutralityThe single-screw rubbing drying machine reduces plastic moisture content to below 3%, enhancing processing efficiency and reducing energy consumption during drying. The energy-efficient design helps businesses achieve emission reduction targets, supporting sustainable development.

- Broad Applications to Reduce Landfill Waste

The system is suitable for processing agricultural plastic films, PP woven bags, bulk bags, and other film plastics, reducing the likelihood of plastic waste entering landfills and mitigating soil pollution.

GEORDING's Crushing, Washing, and Drying Whole Plant Facilitytransforms plastic waste into reusable materials through efficient processing, reducing environmental burdens. From pollution reduction to resource regeneration, the equipment plays a vital role in the circular economy, preventing ecological harm from plastic waste and advancing businesses toward carbon neutrality and sustainable goals.

If you want to contribute to environmental protection and improve your recycling efficiency, contact GEORDING today! We'll provide customized solutions to create a green future together.